Overview of CABINET VISION

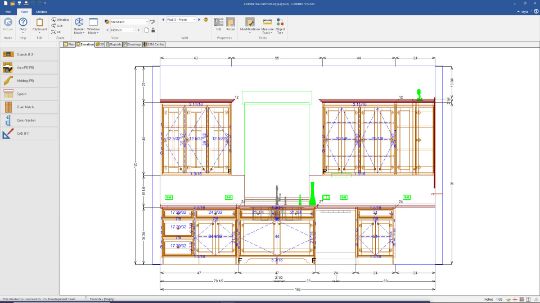

Core Cabinets

Core Cabinets is one of the central components of CABINET VISION. Intuitively easy-to-use, it allows you to create on-screen three-dimensional presentations of the final product while simultaneously generating the necessary production information for the shop floor.

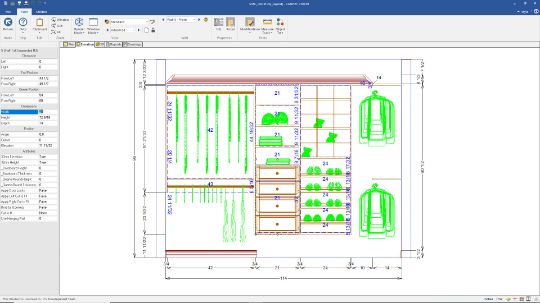

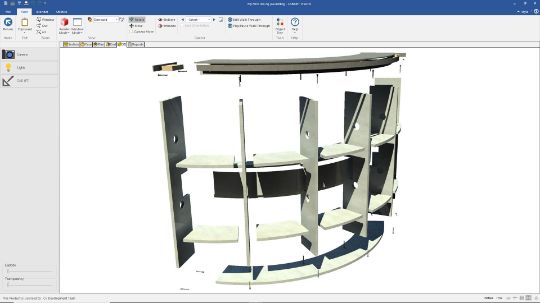

Core closets

Core Closets is a core element of CABINET VISION, providing you with all the essential tools for manufacturing closets. Designed for ease-of-use, Core Closets enables the creation of on-screen three-dimensional presentations of the final product while at the same time generating the production information required on the shop floor. Core Closets integrates 3D renderings, material requirements, assembly sheets and cutlists in a single system. It helps make you more competitive by quickly and accurately estimating the cost of every job and keeping track of expenditure.

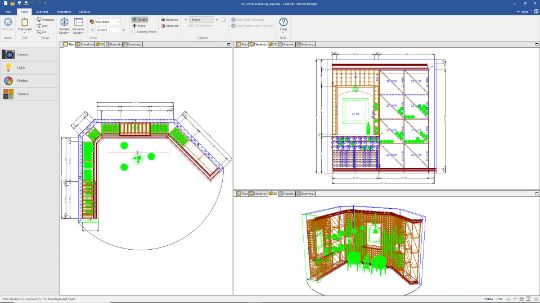

Cabinet vision design

CABINET VISION Design supports sales and profitability by creating professional, accurate designs, renderings and pricing estimates. Its interface is easy to use for both simple and complex projects, enabling designers to give customers a true representation of the look and cost of the finished product. CABINET VISION Design comes in three possible configurations, cabinets, closets, or both and lets you draw on a smart catalogue of products and objects so you can consistently design to manufacturers’ standards.

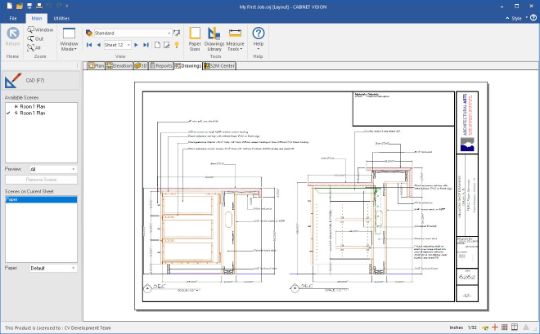

X2D CAD

Creating accurately annotated drawings with the x2D CAD multiplier makes it simpler to communicate design intent to architects and contractors. x2D CAD comes with a host of tools and capabilities, including the automatic updating of part information from the live drawing.

xBidding

Complete control over bidding and estimation

The xBidding multiplier is a simple yet powerful tool that accurately generates bid data so that you can put forward bids that are both competitive and profitable. xBidding performs a complex calculation based on the material, labour and other costs of the final engineered product, thereby giving you a clear indication of your room for negotiation on price. The smart bidding system also makes it easy to discuss design changes with customers without having to recalculate bids from scratch.

xCountertops

Making countertop construction part of a seamless manufacturing process.

The xCountertop multiplier is fully integrated with CABINET VISION, making it possible for you to configure countertop construction with the same Assembly Manager interface used for cabinets, closets, and drawers. xCountertop calculates cut lists for countertops, automatically updates manufacturing operations with changes made in design and makes it easy to configure build-up, draw-bolts, dog bones, alignment boring and other machining on your countertops. All while giving you a clear overview of costs.

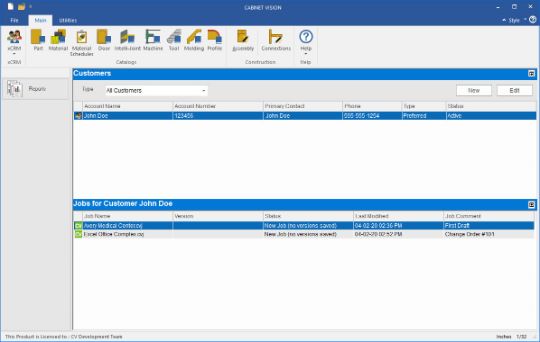

xcrm

Managing business seamlessly with customers, suppliers and contractors

The xCRM multiplier makes it easy for you to create and manage your customer contact lists and related jobs. With xCRM it is simple to seamlessly track revisions to customers' jobs, ensuring final products accurately match your customers' expectation while saving time on searches. xCRM's centralised interface allows you and your team to view and access the CABINET VISION jobs you are currently working on so you can deliver projects on time. It is also a powerful tool for sub-contractors who need to track and deliver multiple projects for contractors.

xmachining

xMachining is the most flexible, powerful and automated CNC software in the woodworking market. Operating with a full range of machines, including CNC routers, drill and dowel, chop saws, panel saws, haunching machines and edgebanders. xMachining has the capability to intelligently programme machinery by analysing part geometry and automatically creating toolpaths, choosing the right tool, and selecting the speed and feed rates. And if you use multiple types of CNC machinery you can rely on xMachining to automate workflows and send the right part, to the right machine, at the right time.

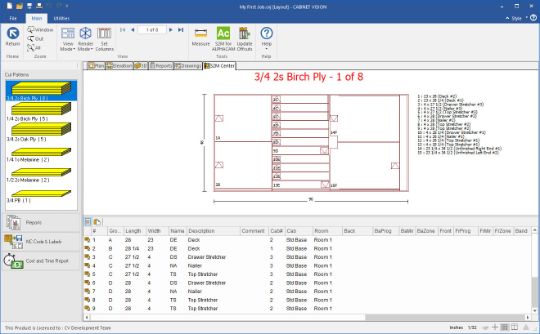

xoptimizer

xOptimizer maximises panel saw yield

The Panel Optimizer multiplier is ideal if you are seeking to maximise material yield and reduce waste. It also increases output by eliminating the need to calculate patterns manually.

Fully integrated with CABINET VISION, it allows you to quickly and easily convert cut lists into patterns for import directly to an NC panel saw (with the +Saw addition) or to create printed patterns for a manual sawyer. With built-in Offcut Management, the system will instruct the sawyer which offcuts to use from job to job, maximising the use of material.

xRendering

A photorealistic render that lets customers visualise the final product

Customers are much more likely to place orders with you if they can visualise how designs will look once they are built and in use in their home or business. The xRendering multiplier gives you an important competitive advantage by creating photorealistic renderings in minutes, using the latest rendering technology. You can work with your customers to make changes to designs in seconds, whether to floors, wall coverings, countertops, wood species, stain colors, knobs or other hardware. In this way customers can take ownership of designing their dream layout, helping you to drive higher value sales.

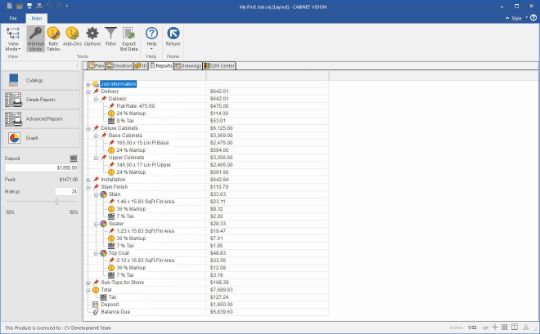

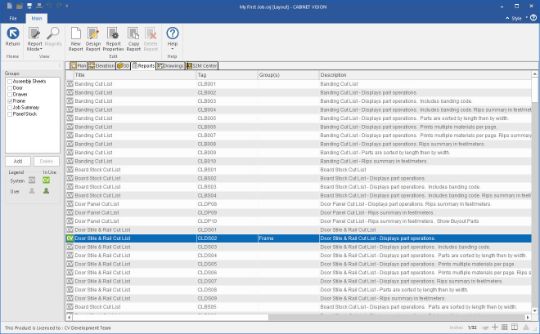

xReporting

xReporting gives you access to over 150 predefined reports as well as a custom report editor, making it easy to share clear, concise information with the relevant departments throughout your business. The xReporting multiplier saves time by allowing you to create report groups containing multiple reports that can be printed with a single click. And because it is integrated with CABINET VISION it automatically updates reports when changes are made to the job design or project specifications.

xShaping

Simplify the shaping of individual parts, including toe notches, cut out around columns, clip and radius corners

Not all jobs involve right angles. Wall angles, floor levels and customer preferences can pose irregular shaping challenges. xShaping provides the capability to parametrically shape assemblies, parts, and routes utilising both simple and advanced constraints. xShaping also gives access to the CAM Editor for easily adding operations to parts for machining, such as grommet holes, electrical chases and plumbing cutouts.